I wanted to change the top of one camera pole to have three turret cameras instead of two cameras currently mounted.

The prior, two headed mount I printed in black PETG has held up well through several years weather.

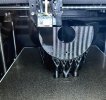

It's going to take a day and a half to print in PETG. 1/4 of the way through....

The prior, two headed mount I printed in black PETG has held up well through several years weather.

It's going to take a day and a half to print in PETG. 1/4 of the way through....